<body><script type="text/javascript">

function setAttributeOnload(object, attribute, val) {

if(window.addEventListener) {

window.addEventListener('load',

function(){ object[attribute] = val; }, false);

} else {

window.attachEvent('onload', function(){ object[attribute] = val; });

}

}

</script>

<div id="navbar-iframe-container"></div>

<script type="text/javascript" src="https://apis.google.com/js/platform.js"></script>

<script type="text/javascript">

gapi.load("gapi.iframes:gapi.iframes.style.bubble", function() {

if (gapi.iframes && gapi.iframes.getContext) {

gapi.iframes.getContext().openChild({

url: 'https://www.blogger.com/navbar.g?targetBlogID\x3d10707316\x26blogName\x3dDierksenkougan+Brewlog\x26publishMode\x3dPUBLISH_MODE_BLOGSPOT\x26navbarType\x3dBLACK\x26layoutType\x3dCLASSIC\x26searchRoot\x3dhttps://dierksenkouganmicrobrew.blogspot.com/search\x26blogLocale\x3den_US\x26v\x3d2\x26homepageUrl\x3dhttp://dierksenkouganmicrobrew.blogspot.com/\x26vt\x3d1769034442845103088',

where: document.getElementById("navbar-iframe-container"),

id: "navbar-iframe"

});

}

});

</script>

Employment

I didn't want to jinx anything by posting this before the fact, but I received a call from Bell's Brewery today, after having an interview last Tuesday, and I got a job! I'll be working all summer at the Bell's General Store (unfortunately not their brewing facility), which is where I buy all my homebrewing supplies, as well as on and off in the Eccentric Cafe, their Kalamazoo bar. Should be easy work in a great environment, and hopefully a foot in the door for moving upward. Basically, I'm excited just to be surrounded by brewing stuff all day, plus maybe I'll get a discount for my own purposes. We'll see next week when I meet with my manager for scheduling and details and such.

Other equally big news: I received an email from the Head Brewer and Production Leader of Arcadia Brewing Co. in Battle Creek, MI, an easy 30 minute drive from here. I had sent in an application to work in their brewing facility about early March, and it looks like they're interested. I have an interview on Monday morning with the Head Brewer Mike, but I don't have any details yet regarding what they're looking for or even my chances of getting a job. I'll make sure to keep you all updated through the brewlog.

Cross your fingers!

Sam

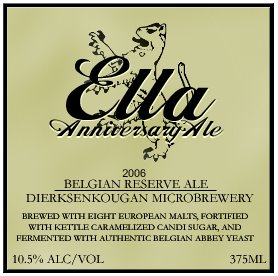

PS: The Kolsch will be going in bottles tomorrow. Ella will be close behind.

Cold Conditioning

Just a quick update:

The still unnamed Kolsch is cold conditioning in secondary right now, and will be there another three weeks before I bottle her up. Certain styles, especially ones that demand a certain crispness and lack of flavor complexity (like lagers, pale ales, and Kolsches), can benefit both in flavor and visual clarity from being cold conditioned and stored at near-freezing temperatures for months at a time. It allows most of the yeast to fall out of suspension, leaving the beer crystal clear, and also helps dampen yeast byproducts that cause fruity and spicy flavors in the beer. Of course, these flavors are welcome in many and most styles, but are less desired in others.

Ella the Anniversary Ale is hanging out with the Kolsch, and I'm still researching whether the cold conditioning will do her harm or good. It will certainly clear her up, which would be nice, but I have a trade off decision to make: Belgian ales like this one are known for their strong alcohol content and their complex, yeasty character. The cold will dampen the alcohol bite, which is nice, but also dampen some of that complexity. So I might take her out of the freezer and store her in a closet for a bit longer.

Regardless, both will be bottled in three weeks.

Meanwhile, Eva is all ready to drink. She's very very tasty; anyone who likes Bell's Brown or Newcastle should try a bottle. She's a far cry from my typical bitter beer: slightly sweet, but not cloyingly so, and very malty. Lots of subtle flavors to pick out and appreciate. She'll be around awhile (I'm still polishing off Annabelle and Rachel), so let me know if you'd like some.

Kolsch and All Grain

Another new brew is bubbling away in the fermentor today after brewing yesterday. The beer is an as-of-yet-unnamed German-style Kolsch, a very pale, straw-colored beer that is the ale's response to your typical, run of the mill lager (but better). The result is something like your favorite high-quality pilsener, like Corona or Red Stripe, but with a slightly more pronounced hop flavor and some subtle fruity character from the special German yeast strain. In other words, something most beer drinkers should enjoy, but complex enough to not fall in the category of "cheap beer."

Yesterday marked a pretty important milestone in my brewing timeline, as the Kolsch was my first all grain beer, which means that instead of partially using malt extract, the beer was made completely from straight barley grain. The difference between extract and straight grain is basically the difference between getting orange juice concentrate instead of getting fresh oranges and squeezing your own; for one, fresh all grain beers taste better, but require more equipment and much more effort. Things like water quality, pH, and mineral content come into play where they hadn't mattered much before, because it's the brewer's job to get the sugars out of the grains, rather than the producers of the malt extract.

It was a decent brew day, but my effiency on my all grain system was disappointing. Good brewers get 75-80% of the grains' sugars out of them for brewing purposes, while 70% is acceptable. My efficiency was just under 60%, while I had expected 70%. That means my beer suffered about a 15% decrease in alcohol and body for the same amount of base grain, which is still acceptable for the style (this Kolsch will end up being quite light at about 4.5% alcohol by volume, which is on the low range of the average content for the style). Practice will make perfect, though, as I still need to study some water chemistry information and buy a few more ingredients (including buffer salts that keep the water pH at a perfect 5.2) to really jump head first into all grain. But overall, not a failure of a brew day. The beer should turn out just fine, after all.

Eva, the 10-Malt Brown Ale, got bottled while I simultanously brewed the Kolsch, and should be ready in under two weeks. I thought it might need more time to mature, but the alcohol content on her being lower than expected as well (she should fall at a normal 6.0% or so) meant that she was plenty ready in just a few weeks. Preliminary tastings are promising.

That's all for now. Not sure what is on deck, but I'll post after I've gotten back to the books, bought my needed ingredients, and I feel like I've perfected the all grain procedure. Hopefully weather improves as well, as I'd like the next brew to be an outdoor one with my new burner hooked up to a propane tank, sitting in the lawn chair and soaking up the sun. Until then....

Sam